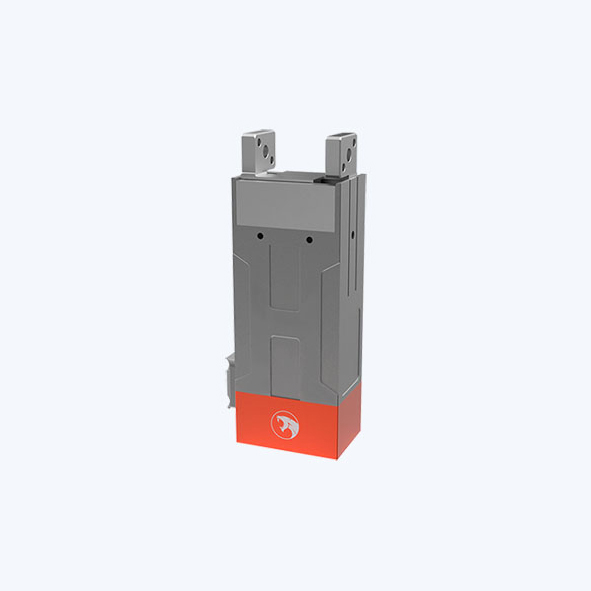

Collaborative Robot Gripper – Z-EFG-20P Electric Gripper

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent actuator/Automation solutions

Application

SCIC Z-EFG series robot grippers are in small size with a built-in servo system, which makes it possible to achieve precise control of speed, position, and clamping force. SCIC cutting edge gripping system for automation solutions will let you open new possibilities for automating tasks that you never thought possible.

Feature

● Accuracy Force Control, Suitable for the clamping request in small area.

● Big Clamping Force, Accuracy Force Control

● Dynamic Mode and Stroke Adjustable

● Compact Structure, Flexible to Install.

● Drive and Controller Integrated to Support Soft Clamping.

The Force, Bit and Speed can be controlled by Modbus

Big Clamping Force

Total stroke is 20mm, clamping force is 30-80N

Accurancy Control

Repeatability is ±0.02mm

Long Lifespan

Tens of million cycles, beyong of air gripper

Total Stroke

The shortest time of total stroke is 0.40s.

Control Mode

485, I/O Input and Output

Movement Mode

Parallel Movement

● Promoting a revolution in the replacement of pneumatic grippers by electric grippers, first electric gripper with integrated servo system in China.

● Perfect replacement for air compressor + filter + solenoid valve + throttle valve + pneumatic gripper

● Multiple cycles service life, consistent with the traditional Japanese cylinder

Specification Parameter

|

Model No. Z-EFG-20P |

Parameters |

|

Total stroke |

20mm adjustable |

|

Gripping force |

30-80N adjustable |

|

Repeatability |

±0.02mm |

|

Recommended gripping weight |

≤0.8kg |

|

Transmission mode |

Gear rack + Cross Roller guide |

|

Grease replenishment of moving components |

Every six months or 1 million movements / time |

|

One-way stroke motion time |

0.40s |

|

Movement mode |

Two fingers move horizontally |

|

Weight |

0.46kg |

|

Dimensions(L*W*H) |

44*30*124.7mm |

|

Operating voltage |

24V±10% |

|

Rated current |

0.2A |

|

Peak current |

1A |

|

Power |

5W |

|

Protection class |

IP20 |

|

Motor type |

DC brushless |

|

Operating temperature range |

5-55℃ |

|

Operating humidity range |

RH35-80 (No frost) |

|

Permissible static load in vertical direction |

|

| Fz: | 150N |

|

Permissible torque |

|

|

Mx: |

2.1 N.m |

|

My: |

2.34 N.m |

| Mz: | 2 N.m |

Big Clamping Force, Accuracy Force Control

The electric gripper of Z-EFG-20P is to utilize special transmission design and drive algorithm compensation, its clamping force is 30-80N adjustable, total stroke is 20mm, and its repeatability is ±0.02mm.

Dynamic Mode and Stroke Adjustable

The movement mode of electric gripper is 2-finger parallel the shortest time of single stroke is just 0.40s, clamping weight is ≤0.8kg, it can meet the clamping request for stable production.

Compact Structure, Flexible to Install.

The size of Z-EFG-20P is L44*W30*H124.7mm, its structure is compact, to support above 5 installation modes, its controller is built-in, small room occupying, it can be easy to deal with various of clamping tasks.

Drive and Controller Integrated, to Support Soft Clamping.

The tail part of Z-EFG-20P can be changed easily, customer can design the tail part according to their clamping objects, to guarantee the electric gripper completing the clamping tasks at the most extent.

Load Center of Gravity Offset

Our Business