Product center

Founded in 2020, SCIC-Robot is an industrial collaborative robot and system supplier.

- 6 Axis Robotic Arms

- Servo Electric Cylinder

- AGV and AMR

- Grippers

- EOATs

- Multi Feeder System

- Scara Robotic Arms

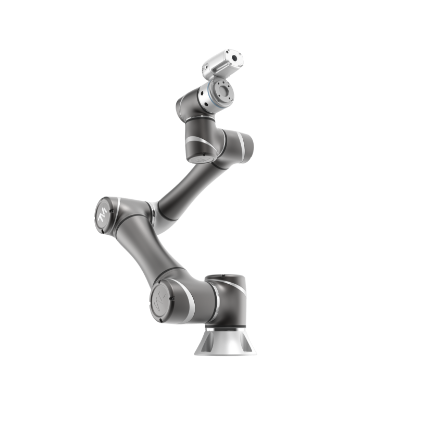

NEW GENERATION AI COBOT SERIES – TM25S 6 Axis AI Cobot

NEW GENERATION AI COBOT SERIES – TM25S 6 Axis AI Cobot

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

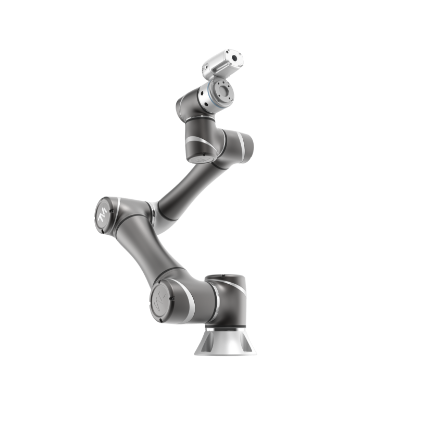

NEW GENERATION AI COBOT SERIES – TM12S 6 Axis AI Cobot

NEW GENERATION AI COBOT SERIES – TM12S 6 Axis AI Cobot

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

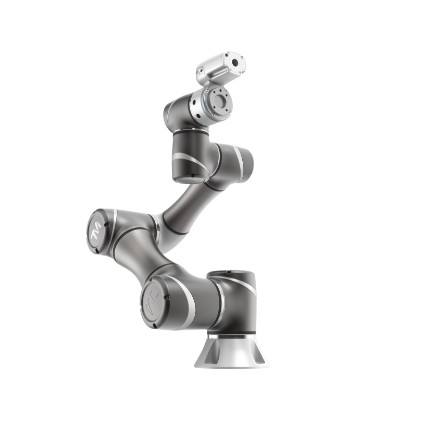

NEW GENERATION AI COBOT SERIES – TM14S 6 Axis AI Cobot

NEW GENERATION AI COBOT SERIES – TM14S 6 Axis AI Cobot

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

NEW GENERATION AI COBOT SERIES – TM5S 6 Axis AI Cobot

NEW GENERATION AI COBOT SERIES – TM5S 6 Axis AI Cobot

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

NEW GENERATION AI COBOT SERIES – TM7S 6 Axis AI Cobot

NEW GENERATION AI COBOT SERIES – TM7S 6 Axis AI Cobot

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

COLLABORATIVE ROBOTIC ARMS – CR16 6 Axis Robotic Arm

COLLABORATIVE ROBOTIC ARMS – CR16 6 Axis Robotic Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

COLLABORATIVE ROBOTIC ARMS – CR10 6 Axis Robotic Arm

COLLABORATIVE ROBOTIC ARMS – CR10 6 Axis Robotic Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

COLLABORATIVE ROBOTIC ARMS – CR5 6 Axis Robotic Arm

COLLABORATIVE ROBOTIC ARMS – CR5 6 Axis Robotic Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

COLLABORATIVE ROBOTIC ARMS – CR3 6 Axis Robotic Arm

COLLABORATIVE ROBOTIC ARMS – CR3 6 Axis Robotic Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

TM AI COBOT SERIES – TM5-900 6 Axis AI Cobot

TM AI COBOT SERIES – TM5-900 6 Axis AI Cobot

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

TM AI COBOT SERIES – TM5M-900 6 Axis AI Cobot

TM AI COBOT SERIES – TM5M-900 6 Axis AI Cobot

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

TM AI COBOT SERIES – TM5M-700 6 Axis AI Cobot

TM AI COBOT SERIES – TM5M-700 6 Axis AI Cobot

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

Stepping Series Actuator – Z-Mod-ST-59B Electric Actuator

Stepping Series Actuator – Z-Mod-ST-59B Electric Actuator

Main Category

Intelligent Electric Actuator /Smart Electric Actuator / Electric Actuator /Intelli...

More

Stepping Series Actuator – Z-Mod-ST-54B Electric Actuator

Stepping Series Actuator – Z-Mod-ST-54B Electric Actuator

Main Category

Intelligent Electric Actuator /Smart Electric Actuator / Electric Actuator /Intelli...

More

Stepping Series Actuator – Z-Mod-ST-66SS Electric Actuator

Stepping Series Actuator – Z-Mod-ST-66SS Electric Actuator

Main Category

Intelligent Electric Actuator /Smart Electric Actuator / Electric Actuator /Intelli...

More

Stepping Series Actuator – Z-Mod-ST-52SS Electric Actuator

Stepping Series Actuator – Z-Mod-ST-52SS Electric Actuator

Main Category

Intelligent Electric Actuator /Smart Electric Actuator / Electric Actuator /Intelli...

More

KK Series Actuator – Z-Mod-KK-86-20SE Electric Actuator

KK Series Actuator – Z-Mod-KK-86-20SE Electric Actuator

Main Category

Intelligent Electric Actuator /Smart Electric Actuator / Electric Actuator /Intelli...

More

KK Series Actuator – Z-Mod-KK-60-10SE Electric Actuator

KK Series Actuator – Z-Mod-KK-60-10SE Electric Actuator

Main Category

Intelligent Electric Actuator /Smart Electric Actuator / Electric Actuator /Intelli...

More

Servo Series Actuator – Z-Mod-SE-120-40SE Intelligent Electric Actuator

Servo Series Actuator – Z-Mod-SE-120-40SE Intelligent Electric Actuator

Main Category

Intelligent Electric Actuator /Smart Electric Actuator / Electric Actuator /Intelli...

More

Servo Series Actuator – Z-Mod-SE-102-40SE Intelligent Electric Actuator

Servo Series Actuator – Z-Mod-SE-102-40SE Intelligent Electric Actuator

Main Category

Intelligent Electric Actuator /Smart Electric Actuator / Electric Actuator /Intelli...

More

Servo Series Actuator – Z-Mod-SE-82-20SE Intelligent Electric Actuator

Servo Series Actuator – Z-Mod-SE-82-20SE Intelligent Electric Actuator

Main Category

Intelligent Electric Actuator /Smart Electric Actuator / Electric Actuator /Intelli...

More

Servo Series Actuator – Z-Mod-SE-73-20SE Intelligent Electric Actuator

Servo Series Actuator – Z-Mod-SE-73-20SE Intelligent Electric Actuator

Main Category

Intelligent Electric Actuator /Smart Electric Actuator / Electric Actuator /Intelli...

More

Servo Series Actuator – Z-Mod-SE-54-10SE Intelligent Electric Actuator

Servo Series Actuator – Z-Mod-SE-54-10SE Intelligent Electric Actuator

Main Category

Intelligent Electric Actuator /Smart Electric Actuator / Electric Actuator /Intelli...

More

Servo Series Actuator – Z-Mod-SE-44-10SE Intelligent Electric Actuator

Servo Series Actuator – Z-Mod-SE-44-10SE Intelligent Electric Actuator

Main Category

Intelligent Electric Actuator /Smart Electric Actuator / Electric Actuator /Intelli...

More

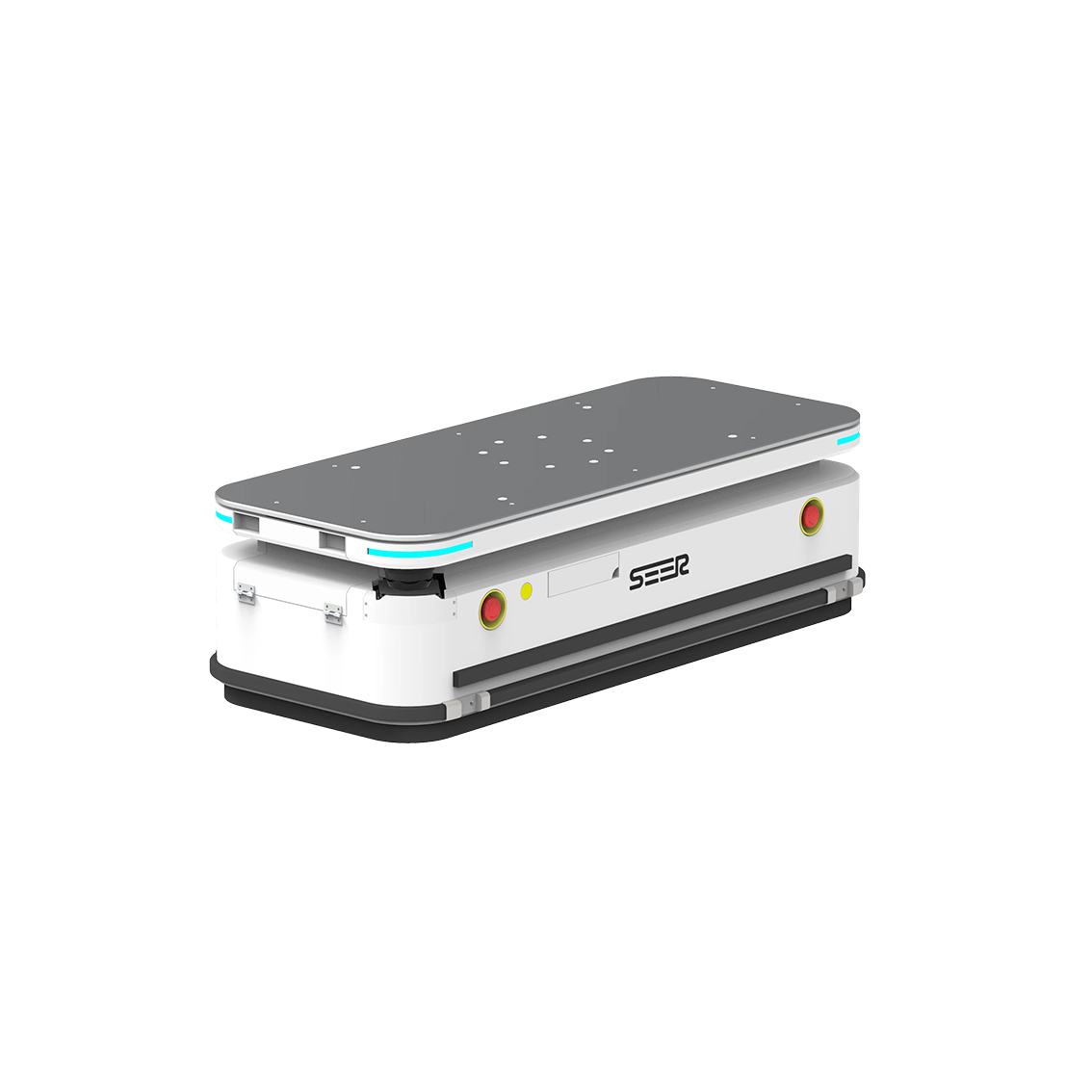

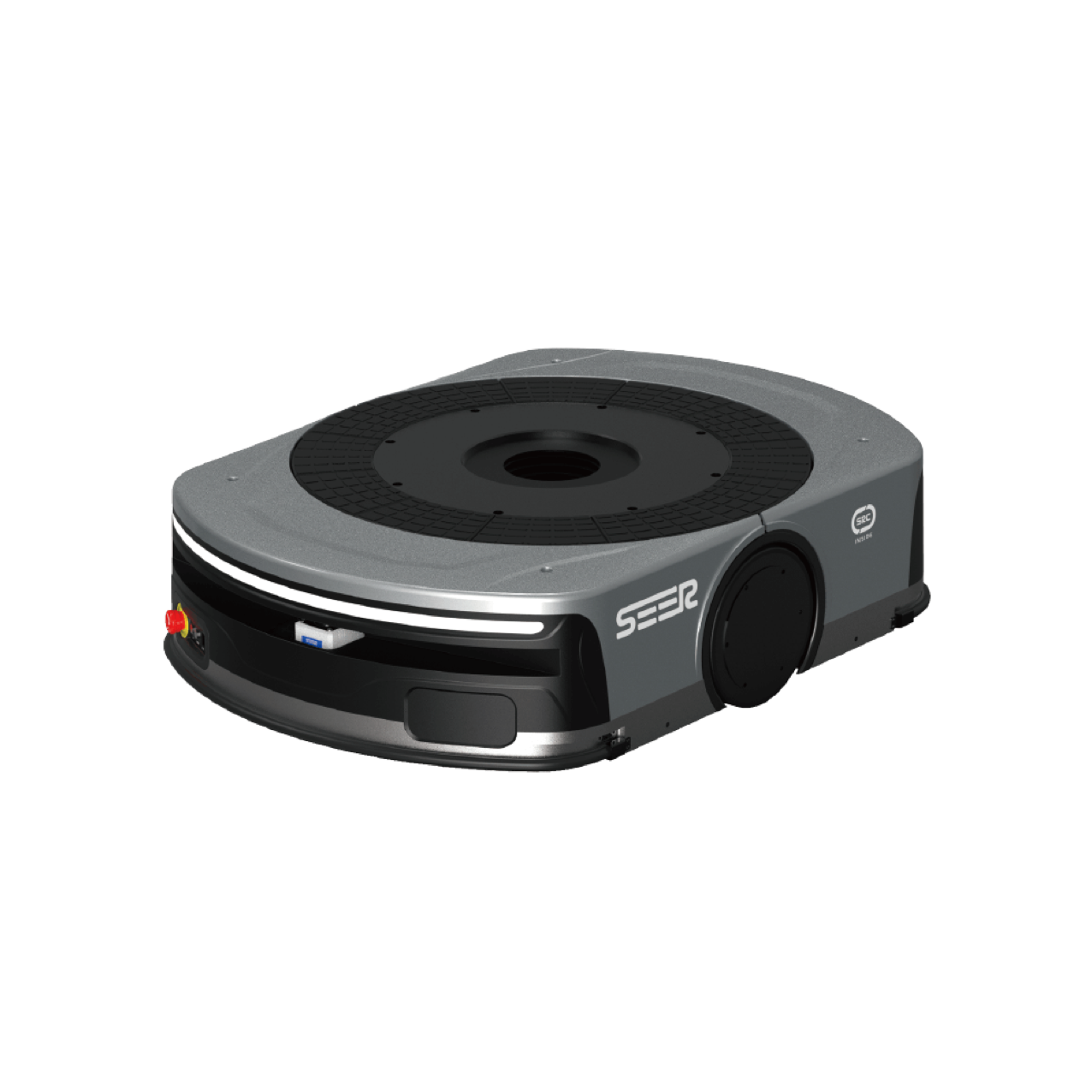

AMR/AGV Mode – A Next-generation Automatic Transport Robot

AMR/AGV Mode – A Next-generation Automatic Transport Robot

Main Category

AGV AMR / autonomous mobile robot/jack up lifting AGV AMR / AGV automatic guid...

More

SMART FORKLIFT – SFL-CDD16 Laser SLAM Stacker Smart Forklift

SMART FORKLIFT – SFL-CDD16 Laser SLAM Stacker Smart Forklift

Main Category

AGV AMR / AGV automatic guided vehicle / AMR autonomous mobile robot / AMR rob...

More

SMART FORKLIFT – SFL-CBD15 Laser SLAM Small Ground Smart Forklift

SMART FORKLIFT – SFL-CBD15 Laser SLAM Small Ground Smart Forklift

Main Category

AGV AMR / AGV automatic guided vehicle / AMR autonomous mobile robot / AMR rob...

More

SMART FORKLIFT – SFL-CDD14-CE Laser SLAM Small Stacker Smart Forklift

SMART FORKLIFT – SFL-CDD14-CE Laser SLAM Small Stacker Smart Forklift

Main Category

AGV AMR / AGV automatic guided vehicle / AMR autonomous mobile robot / AMR rob...

More

JACKING ROBOTS – Laser SLAM Lifting Robot SJV-SW1500

JACKING ROBOTS – Laser SLAM Lifting Robot SJV-SW1500

Main Category

AGV AMR / jack up lifting AGV AMR / AGV automatic guided vehicle / AMR autonom...

More

JACKING ROBOTS – Laser SLAM Lifting Robot SJV-W1000

JACKING ROBOTS – Laser SLAM Lifting Robot SJV-W1000

Main Category

AGV AMR / jack up lifting AGV AMR / AGV automatic guided vehicle / AMR autonom...

More

JACKING ROBOTS – Rotary Lifting Robot SJV-SW500

JACKING ROBOTS – Rotary Lifting Robot SJV-SW500

Main Category

AGV AMR / jack up lifting AGV AMR / AGV automatic guided vehicle / AMR autonom...

More

JACKING ROBOTS – Omni-Directional Lifting Robot SJV-W600DS-DL

JACKING ROBOTS – Omni-Directional Lifting Robot SJV-W600DS-DL

Main Category

AGV AMR / jack up lifting AGV AMR / AGV automatic guided vehicle / AMR autonom...

More

JACKING ROBOTS – Rotary Lifting Robot AMB-800K

JACKING ROBOTS – Rotary Lifting Robot AMB-800K

Main Category

AGV AMR / jack up lifting AGV AMR / AGV automatic guided vehicle / AMR autonom...

More

JACKING ROBOTS – Safety Lifting Robot AMB-500JS

JACKING ROBOTS – Safety Lifting Robot AMB-500JS

Main Category

AGV AMR / jack up lifting AGV AMR / AGV automatic guided vehicle / AMR autonom...

More

JACKING ROBOTS – Satety Robot AMB-1000JS

JACKING ROBOTS – Satety Robot AMB-1000JS

Main Category

AGV AMR / jack up lifting AGV AMR / AGV automatic guided vehicle / AMR autonom...

More

STANDARD AMRS – Auto Mobile Bases AMB-300/AMB-300-D

STANDARD AMRS – Auto Mobile Bases AMB-300/AMB-300-D

Main Category

AGV AMR / jack up lifting AGV AMR / AGV automatic guided vehicle / AMR autonom...

More

GRIPPER MODULE SERIES – FPT Three-fingers Translational Gripper

GRIPPER MODULE SERIES – FPT Three-fingers Translational Gripper

Main Category

Robot Tool Changer / End-of-Arm Tool Changer (EOAT) / Quick Change System / Automat...

More

GRIPPER MODULE SERIES – FPT Two-fingers Translational Gripper

GRIPPER MODULE SERIES – FPT Two-fingers Translational Gripper

Main Category

FPT Two-fingers Translational Gripper / two-finger gripper / two-finger gripper des...

More

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-100-26 Slim-type Electric Parallel Gripper

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-100-26 Slim-type Electric...

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent act...

More

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-50-40 Slim-type Electric Parallel Gripper

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-50-40 Slim-type Electric ...

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent act...

More

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-50-26 Slim-type Electric Parallel Gripper

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-50-26 Slim-type Electric ...

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent act...

More

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-15-26 Slim-type Electric Parallel Gripper

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-15-26 Slim-type Electric ...

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent act...

More

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-15-10 Slim-type Electric Parallel Gripper

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-15-10 Slim-type Electric ...

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent act...

More

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-8-14 Slim-type Electric Parallel Gripper

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-8-14 Slim-type Electric P...

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent act...

More

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-5-26 Slim-type Electric Parallel Gripper

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-5-26 Slim-type Electric P...

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent act...

More

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-2-12 Slim-type Electric Parallel Gripper

DH ROBOTICS SERVO ELECTRIC GRIPPER PGE SERIES – PGE-2-12 Slim-type Electric P...

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent act...

More

DH ROBOTICS SERVO ELECTRIC GRIPPER RGD SERIES – RGD-35-30 Electric Direct Drive Rotaty Gripper

DH ROBOTICS SERVO ELECTRIC GRIPPER RGD SERIES – RGD-35-30 Electric Direct Dri...

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent act...

More

DH ROBOTICS SERVO ELECTRIC GRIPPER RGD SERIES – RGD-35-14 Electric Direct Drive Rotaty Gripper

DH ROBOTICS SERVO ELECTRIC GRIPPER RGD SERIES – RGD-35-14 Electric Direct Dri...

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent act...

More

GRIPPER MODULE SERIES – FPT Three-fingers Translational Gripper

GRIPPER MODULE SERIES – FPT Three-fingers Translational Gripper

Main Category

Robot Tool Changer / End-of-Arm Tool Changer (EOAT) / Quick Change System / Automat...

More

GRIPPER MODULE SERIES – FPT Two-fingers Translational Gripper

GRIPPER MODULE SERIES – FPT Two-fingers Translational Gripper

Main Category

FPT Two-fingers Translational Gripper / two-finger gripper / two-finger gripper des...

More

QUICK CHANGER SERIES – QC-200 Round Manual Quick Changer

QUICK CHANGER SERIES – QC-200 Round Manual Quick Changer

Main Category

Robot Tool Changer / End-of-Arm Tool Changer (EOAT) / Quick Change System / Au...

More

QUICK CHANGER SERIES – QC-160 Round Manual Quick Changer

QUICK CHANGER SERIES – QC-160 Round Manual Quick Changer

Main Category

Robot Tool Changer / End-of-Arm Tool Changer (EOAT) / Quick Change System / Au...

More

QUICK CHANGER SERIES – QC-150 Round Manual Quick Changer

QUICK CHANGER SERIES – QC-150 Round Manual Quick Changer

Main Category

Robot Tool Changer / End-of-Arm Tool Changer (EOAT) / Quick Change System / Au...

More

QUICK CHANGER SERIES – QC-90 Round Manual Quick Changer

QUICK CHANGER SERIES – QC-90 Round Manual Quick Changer

Main Category

Robot Tool Changer / End-of-Arm Tool Changer (EOAT) / Quick Change System / Au...

More

QUICK CHANGER SERIES – QC-50 Round Manual Quick Changer

QUICK CHANGER SERIES – QC-50 Round Manual Quick Changer

Main Category

Robot Tool Changer / End-of-Arm Tool Changer (EOAT) / Quick Change System / Au...

More

QUICK CHANGER SERIES – QCA-200-D1 A Quick Changer Device at the End of A Robot

QUICK CHANGER SERIES – QCA-200-D1 A Quick Changer Device at the End of ...

Main Category

Robot Tool Changer / End-of-Arm Tool Changer (EOAT) / Quick Change System / Au...

More

QUICK CHANGER SERIES – QCA-S500 A Quick Changer Device at the End of A Robot

QUICK CHANGER SERIES – QCA-S500 A Quick Changer Device at the End of A ...

Main Category

Robot Tool Changer / End-of-Arm Tool Changer (EOAT) / Quick Change System / Au...

More

QUICK CHANGER SERIES – QCA-S350 A Quick Changer Device at the End of A Robot

QUICK CHANGER SERIES – QCA-S350 A Quick Changer Device at the End of A ...

Main Category

Robot Tool Changer / End-of-Arm Tool Changer (EOAT) / Quick Change System / Au...

More

QUICK CHANGER SERIES – QCA-200 A Quick Changer Device at the End of A Robot

QUICK CHANGER SERIES – QCA-200 A Quick Changer Device at the End of A R...

Main Category

Robot Tool Changer / End-of-Arm Tool Changer (EOAT) / Quick Change System / Au...

More

QUICK CHANGER SERIES – QCA-S150 A Quick Changer Device at the End of A Robot

QUICK CHANGER SERIES – QCA-S150 A Quick Changer Device at the End of A ...

Main Category

Robot Tool Changer / End-of-Arm Tool Changer (EOAT) / Quick Change System / Au...

More

Danikor Flexible Feeding System – Multi Feeder System

Danikor Flexible Feeding System – Multi Feeder System

Danikor’s flex feeder provides flexible parts feeding for any automated application featuri...

More

FlexiBowl Parts Feeding System – FlexiBowl 800

FlexiBowl Parts Feeding System – FlexiBowl 800

Main Category

Flex Feeder System / Flex Feeders Flexible Feeder / Flexible Feeding Systems /...

More

FlexiBowl Parts Feeding System – FlexiBowl 650

FlexiBowl Parts Feeding System – FlexiBowl 650

Main Category

Flex Feeder System / Flex Feeders Flexible Feeder / Flexible Feeding Systems /...

More

FlexiBowl Parts Feeding System – FlexiBowl 500

FlexiBowl Parts Feeding System – FlexiBowl 500

Main Category

Flex Feeder System / Flex Feeders Flexible Feeder / Flexible Feeding Systems /...

More

FlexiBowl Parts Feeding System – FlexiBowl 350

FlexiBowl Parts Feeding System – FlexiBowl 350

Main Category

Flex Feeder System / Flex Feeders Flexible Feeder / Flexible Feeding Systems /...

More

FlexiBowl Parts Feeding System – FlexiBowl 200

FlexiBowl Parts Feeding System – FlexiBowl 200

Main Category

Flex Feeder System / Flex Feeders Flexible Feeder / Flexible Feeding Systems /...

More

4 AXIS ROBOTIC ARMS – Z-SCARA Robot

4 AXIS ROBOTIC ARMS – Z-SCARA Robot

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

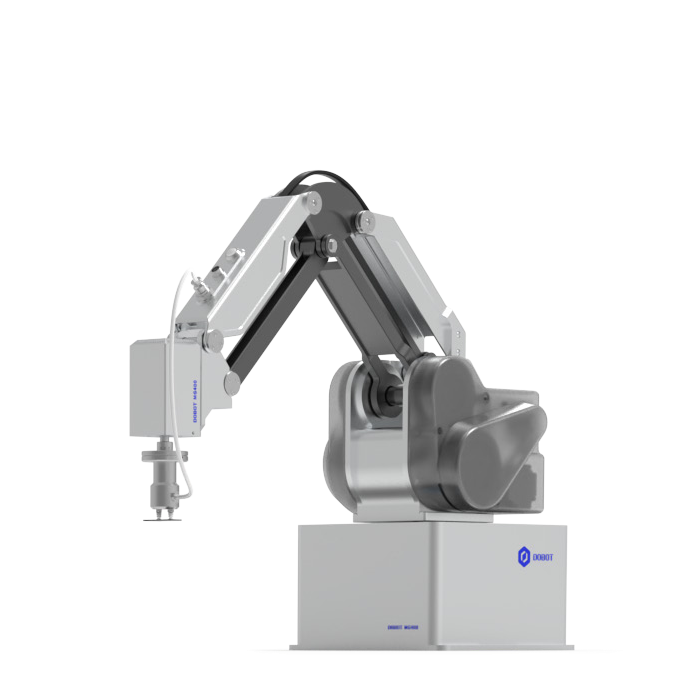

4 AXIS ROBOTIC ARMS – M1 Pro Collaborative SCARA Robot

4 AXIS ROBOTIC ARMS – M1 Pro Collaborative SCARA Robot

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent actuat...

More

4 AXIS ROBOTIC ARMS – MG400 Desktop Collaborative Robot

4 AXIS ROBOTIC ARMS – MG400 Desktop Collaborative Robot

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

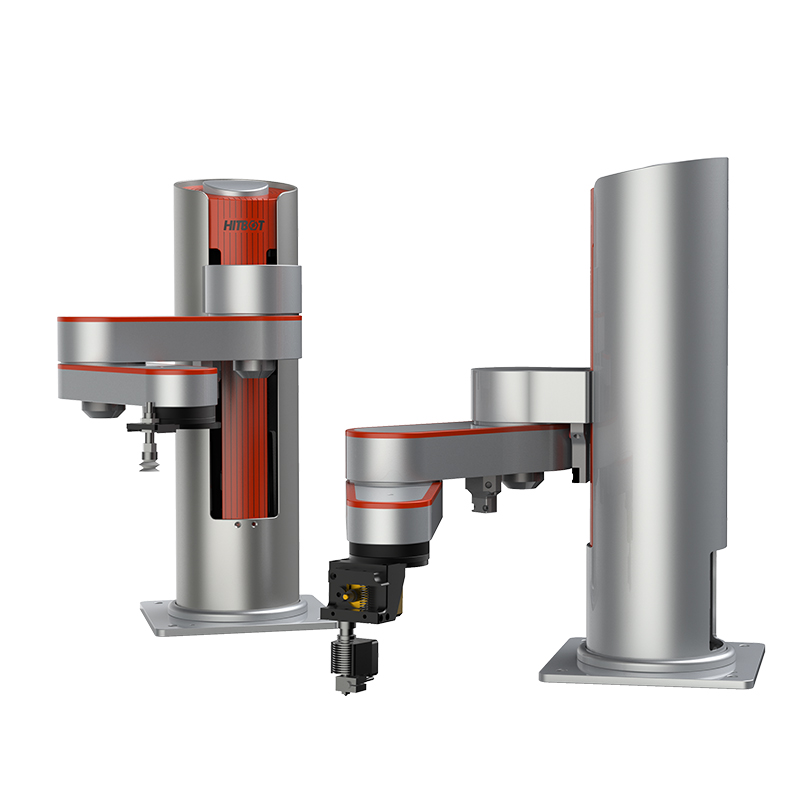

SCARA ROBOTIC ARMS – Z-Arm-2142E Collaborative Robotic Arm

SCARA ROBOTIC ARMS – Z-Arm-2142E Collaborative Robotic Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

SCARA ROBOTIC ARMS – Z-Arm-4160B Collaborative Robotic Arm

SCARA ROBOTIC ARMS – Z-Arm-4160B Collaborative Robotic Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

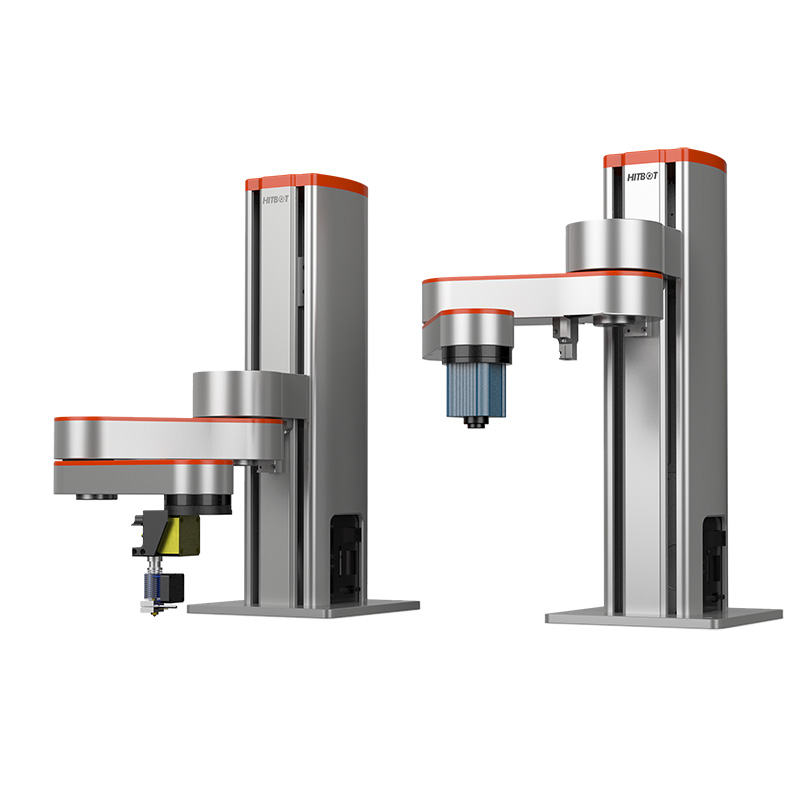

SCARA ROBOTIC ARMS – Z-Arm-4160 Collaborative Robotic Arm

SCARA ROBOTIC ARMS – Z-Arm-4160 Collaborative Robotic Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

SCARA ROBOTIC ARMS – Z-Arm-4150 Collaborative Robotic Arm

SCARA ROBOTIC ARMS – Z-Arm-4150 Collaborative Robotic Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

SCARA ROBOTIC ARMS – Z-Arm-2442B Collaborative Robotic Arm

SCARA ROBOTIC ARMS – Z-Arm-2442B Collaborative Robotic Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

SCARA ROBOTIC ARMS – Z-Arm-2140 Collaborative Robotic Arm

SCARA ROBOTIC ARMS – Z-Arm-2140 Collaborative Robotic Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

SCARA ROBOTIC ARMS – Z-Arm-1632 Collaborative Robotic Arm

SCARA ROBOTIC ARMS – Z-Arm-1632 Collaborative Robotic Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

SCARA ROBOTIC ARMS – Z-Arm-1522 Collaborative Robotic Arm

SCARA ROBOTIC ARMS – Z-Arm-1522 Collaborative Robotic Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

SCARA ROBOTIC ARMS – Z-Arm-1832 Collaborative Robotic Arm

SCARA ROBOTIC ARMS – Z-Arm-1832 Collaborative Robotic Arm

Main Category

Industrial robot arm /Collaborative robot arm / Electric gripper/Intelligent a...

More

about us

Shanghai Chigong Industrial Co., Ltd.

Founded in 2020, SCIC-Robot is an industrial collaborative robot and system supplier, focusing on collaborative robots and their automation products and components, and providing solutions and integration of automation systems. With our technology and service experience in the field of industrial collaborative robots, we customize the design and upgrading of automation stations and production lines for customers in different industries such as automobiles and parts, 3C electronics optics, home appliances, CNC/machining, etc., and provide one-stop services for customers to realize intelligent manufacturing.

0+

Years Industry Experience

0+

Business partner

0+

Country

0+

Professional R&D personnel

solution

SCIC Robot offer high-quality collaborative robots, automation products, and components, along with integrated solutions for automated systems.

Get in touch!

Discover exceptional value with our products and services. Interested? Let's talk business!

Simply click the "Inquire Now" button and tell us about your needs. Our team is ready to provide you with a tailored quote that fits your requirements.

Contact us

hot product

Shanghai Chigong Industrial Co., Ltd.

Danikor Flexible Feeding System – Multi Feeder...

Danikor’s flex feeder provides flexible parts feeding for any automated application featuring varied parts and frequent changeovers. One flex feeder can replace several conventional feeders o...

View more

GRIPPER MODULE SERIES – FPT Three-fingers Tran...

Main Category

Robot Tool Changer / End-of-Arm Tool Changer (EOAT) / Quick Change System / Automatic Tool Changer / Robotic Tooling Interface / Robot Side / Gripper Side / Tooling Flexibility / Quic...

View more

GRIPPER MODULE SERIES – FPT Two-fingers Transl...

Main Category

FPT Two-fingers Translational Gripper / two-finger gripper / two-finger gripper design / 2 finger gripper / FPT parallel translational gripper / FPT dual-finger linear-motion gripper ...

View more

Danikor Flexible Feeding System – Multi Feeder...

GRIPPER MODULE SERIES – FPT Three-fingers Tran...

GRIPPER MODULE SERIES – FPT Two-fingers Transl...

products

NEWS

Shanghai Chigong Industrial Co., Ltd.

The Hands of Industry: A Guide to Cobot Gripper...

The rise of collaborative robots, or cobots, has revolutionized the fac...

Precision in Motion: SCIC SCARA Robotics – Rede...

Beyond the Arm: How SCIC Delivers Turnkey SCARA Workcells for the 3C In...

SCIC Robotics: Driving the Future of Automation...

How SCIC’s Proven Quality, Versatility, and Compatibility Are Optimizin...

Capacity Soars 8x! 400G Optical Module Robot Te...

400G Mass Production Bottleneck Solved: How Robot Pl...

Comprehensive Review: Gripper Technologies for ...

Collaborative robots, or cobots, have transformed automation by enablin...

SCIC EOATs Quick Changers: Effortless Tool Swit...

We unlock the full potential of your collaborative robot with SCIC's pr...