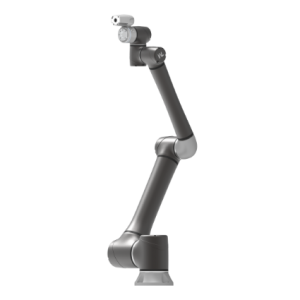

Robotic Arm Robot Manual Industrial Grade Six-Axis Collaborative Handling and Palletizing Handling Robot

Main Category

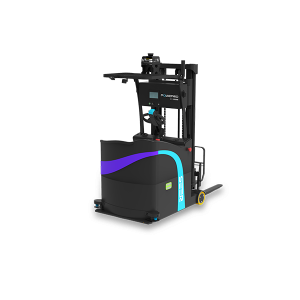

AGV AMR / AGV automatic guided vehicle / AMR autonomous mobile robot / AMR robot stacker / AMR car for industrial material handling / laser SLAM small stacker automatic forklift / warehouse AMR / AMR laser SLAM navigation / AGV AMR mobile robot / AGV AMR chassis laser SLAM navigation / unmanned autonomous forklift / warehouse AMR pallet fork stacker

Application

Warehouse Lift Truck SFL-CPD15-T is equipped with a built-in SRC Series Controller developed by SEER. It can deploy easily without reflectors by adopting Laser SLAM navigation, pick up accurately by pallet identification sensor, be seamlessly connected to dispatching system. This automatic warehouse forklift truck is the preferred transfer warehouse lift machine for goods moving, stacking and palletizing in the factory.

Introducing the Robot Arm Robot Manual Industrial Six-Axis Collaborative Handling and Palletizing Robot, a cutting-edge solution designed to revolutionize manual industrial processes. This highly advanced robotic arm combines precision, flexibility and efficiency to seamlessly optimize handling and palletizing operations.

With its six-axis collaborative design, this handling robot offers unparalleled mobility and adaptability, making it an ideal addition to any industrial environment. Whether you work in manufacturing, logistics, or warehousing, this robot can handle a variety of tasks with ease, from picking and placing items to palletizing heavy items with incredible precision.

The robotic arm is equipped with state-of-the-art sensors and advanced control systems to ensure optimal performance and safety at all times. Collaborative features enable robots to work alongside human operators without compromising their health, maximizing productivity and ensuring a harmonious work environment.

The handling robot's industrial-grade construction guarantees long-lasting durability, even under the most demanding operating conditions. Its powerful motor and rugged mechanical construction allow it to handle heavy loads with ease, significantly reducing the risk of workplace injuries and increasing overall efficiency.

One of the outstanding features of this handling robot is its intuitive manual control system. Operators can easily maneuver the robot using a user-friendly interface, allowing for precise movements and adjustments. This intuitive control system ensures minimal training requirements, allowing operators to quickly adapt to the operation of the robot, ultimately reducing downtime and increasing overall productivity.

Additionally, the handling robot is compatible with a variety of end effectors and can be easily integrated into existing workflows, making it a cost-effective investment. Its ability to adapt to different tasks and work seamlessly with other machines brings undeniable value to any industrial operation.

All in all, the Robotic Arm Robot Manual Industrial Six-Axis Collaborative Handling and Palletizing Robot is an excellent solution for optimizing manual industrial processes. With its precision, flexibility and efficiency, it is guaranteed to increase productivity, safety and ultimately maximize profits. Meet the new era of industrial automation with this state-of-the-art robotic arm.

Feature

·rated load capacity: 1500kg

·Navigation position accuracy: ±10mm

·lifting height: 3300mm

·minimum turning radius: 1514 + 200mm

● Real Laser SLAM Navigation

Trackless path navigation without reflectors makes it really convenient to implement.

● High-precision Recognition

Pallet identification, cage identification and precise goods forking – both efficient and safe.

● 1.5T Load Capacity

Goods carrying with a load of 1.5T;

Repeat accuracy of the point: ±10mm and ±0.5°.

● Flexible Moving and Scheduling

Slender design and small radius of gyration for narrow aisles; flexible scheduling for seamless access.

● All-round Protection Makes it Really Safe

Obstacle avoidance laser, distance sensor, 3D camera plane 360° + headspace protection, and multi-dimensional protection.

● Superb Applicability

Proficient in climbing, crossing ridges, crossing elevators, carrying and stacking.

Related Products

Specification Parameter

Our Business