JACKING ROBOTS – Safety Lifting Robot AMB-500JS

Main Category

AGV AMR / jack up lifting AGV AMR / AGV automatic guided vehicle / AMR autonomous mobile robot / AGV AMR car for industrial material handling / China manufacturer AGV robot / warehouse AMR / AMR jack up lifting laser SLAM navigation / AGV AMR mobile robot / AGV AMR chassis laser SLAM navigation / intelligent logistic robot

Application

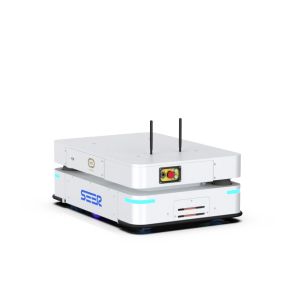

AMB Series Unmanned Chassis AMB (Auto Mobile Base) for agv autonomous vehicle, a universal chassis designed for agv autonomous guided vehicles, provides some features such as map editing and localization navigation. This unmanned chassis for agv cart provides abundant extent interfaces such as I/O and CAN to mount various upper modules together with powerful client software and dispatching systems to help users quickly complete manufacture and application of agv autonomous vehicles. There are four mounting holes on the top of the AMB series unmanned chassis for agv autonomous guided vehicles, which supports arbitrary expansion with jacking, rollers, manipulators, latent traction, display, etc. to achieve multiple applications of one chassis. AMB together with SEER Enterprise Enhanced Digitalization can realize the unified dispatching and deployment of hundreds of AMB products at the same time, which greatly improves the intelligent level of internal logistics and transportation in the factory.

Feature

· Max Load Capacity: 500kg

· Comprehensive Battery Life: 7h

· Lidar Number: 2

· Rotation Diameter: 1460mm

· Driving Speed: ≤1.5m/s

· Positioning Accuracy: ±5,±1mm

● CE Safety Certified, Outstanding Performance & Excellent Safety Standard by Design

Obtion CE certification (ISO 3691-4:2020) and other certifications.

The charging pile is optional for 40 A quick charge, 1 hours of charging for 7 hours of running.

SLAM navigation accuracy of ±5 mm, without reflectors.

With unilateral ≥7 cm distance wide, the AGV could accurately recognize the rack, adjust its position, and drive precisely into it, successfully lift the goods.

Specification Parameter

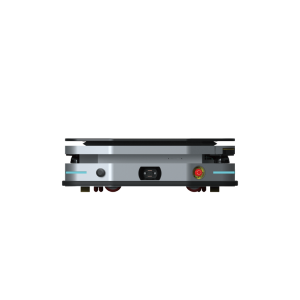

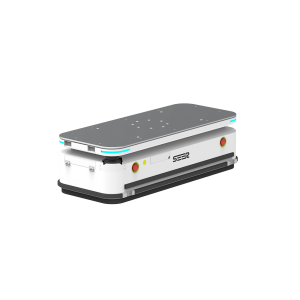

| Product name | AMB-300JZ | AMB-JS | AMB-800K | |

| asicparameters | Navigation method | Laser SLAM | Laser SLAM | Laser SLAM |

| Drive mode | Two-wheel diffe rential | Two-wheel diffe rential | Two-wheel diffe rential | |

| Shell color | Cool Gray | Cool Gray | Black & gray | |

| L*W*H(mm) | 792*580*250 | 1330*952*290 | 980*680*245 | |

| Rotation diameter(mm) | 910 | 1460 | 980 | |

| Weight (with battery)(kg) | 150 | 265 | 150 | |

| Load capacity(kg) | 300 | 500/1000 | 800 | |

| Jacking platform dimensions(mm) | 760*545 | 1300*920 | φ640 | |

| Maximum jacking height(mm) | 60±2 | 60±1 | 60±2 | |

| Performance parameters | Minimum passable width(mm) | 640 | 1050 | 820 |

| Navigation position accuracy(mm)* | ±5 | ±5 | ±5 | |

| Navigation angle accuracy(°)* | ±0.5 | ±1 | ±0.5 | |

| Navigation speed(m/s) | ≤1.5 | ≤1.5 | ≤1.8 | |

| Batteryparameters | Battery specifications(V/Ah) | 48/20(Lithium Iron Phosphate) | 48/40(Lithium Iron Phosphate) | 48/27 (Lithium Iron Phosphate) |

| Comprehensive battery life(h) | 8 | 7 | 8 | |

| Automatic charging parameters(V/A) | 54.6/15 | 54.6/40 | 54.5/15 | |

| Charging time (10-80%)(h) | ≤1 | ≤2 | ≤2 | |

| Charging method | Manual/Automatic | Manual/Automatic | Manual/Automatic | |

| Configurations | Lidar number |

2(SICK nanoScan3+FREE C2)or 2(FREE H1+FREE C2) |

2(SICK nanoScan3) |

1(SICK nanoScan3 Core)or 1(OLEILR-1BS5H) |

| Number of low-position obstacleavoidance photoelectric | 0 | - | 0 | |

| Cargo detection | - | 〇 | - | |

| E-stop button | ● | ● | ● | |

| Speaker | ● | ● | ● | |

| Atmosphere light | ● | ● | ● | |

| Bumperstrip | ● | ● | ● | |

| Functions | Wi-Fi roaming | ● | ● | ● |

| Automatic charging | ● | ● | ● | |

| Shelf recognition | ● | ● | ● | |

| Spin | - | - | ● | |

| Precise location with QR code | 〇 | - | 〇 | |

| QR code navigation | 〇 | - | 〇 | |

| Laser reflector navigation | 〇 | 〇 | 〇 | |

| Certifications | EMC/ESD | - | ● | - |

| UN38.3 | - | ● | ● | |

* Navigation accuracy usually refers to the repeatability accuracy that a robot navigates to the station.

● Standard 〇 Optional None

Our Business