High Performance Industrial 6 Axis Assembly Carry Spray Grind Stacking Material Handling Parts Transfer Spot Welding Packaging Detection Deburring Robot Arm

High Performance Industrial 6 Axis Assembly Carry Spray Grind Stacking Material Handling Parts Transfer Spot Welding Packaging Detection Deburring Robot Arm

Application

SCIC HITBOT Z-Arm cobots with its high automation & sound precision, can free workers from repetitive and fatigue work in various industries and applications, including but not limited to:

- Assembly: screwdriving, part insertion, spot welding, soldering, etc.

- Materials handling: pick and place, grinding, drilling, etc.

- Dispensing: gluing, sealing, painting, etc.

- Inspection and testing, as well as school education.

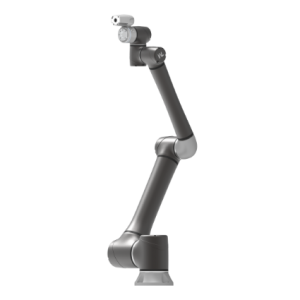

SCIC HITBOT Z-Arm cobots are lightweight 4-axis collaborative robots with drive motor built inside, and no longer require reducers like other traditional scara, reducing the cost by 40%. HITBOT Z-Arm cobots can realize functions including but not limited to 3D printing, material handling, welding, and laser engraving. It is capable of greatly improving the efficiency and flexibility of your work and production.

Features

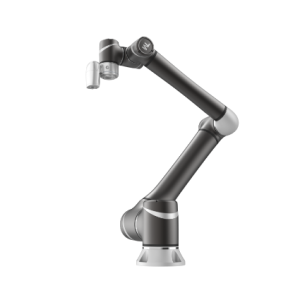

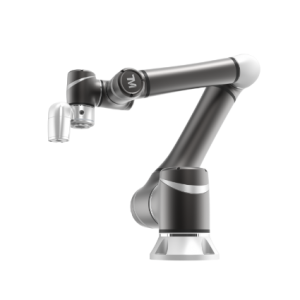

HITBOT Z-Arm 2140

Leading Provider of Lightweight Collaborative Robots

Compact and Precise

Flexible to deploy in various application scenarios

Simple but Versatile

Easy to program and use, hand-held drag teach, support SDK

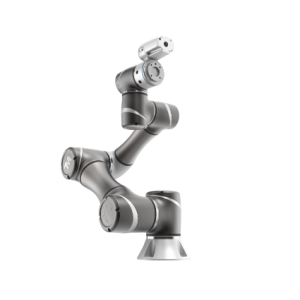

Collaborative and Safe

Collision detection supported, smart human-machine collaboration

High Precision

Repeatability

±0.03mm

High Speed

1255.45mm/s

Heavy Payload

3KG

Extended Arm Reach

J1 200mm

J2 200mm

Extended Work Range

J1 rotation ±90°

J1 rotation ±164°

Z-Axis 210mm

R axis Rotation ±360°

Cost-effective

Industrial Quality Consumer-grade Price

Collaboration

J1 rotation ±90°

Multiple machine Collaboration

Human-machine Collaboration

Communication

Wi-fi Ethernet

Application Show

Circuit board soldering

Visual Sorting

Dispensing

Screwdriving

30 Printing

Laser engraving

Material Sorting

Related Products

Specification Parameter

|

Parameter |

Model |

||

|

Z-Arm 2140C |

|||

|

J1 Axis |

Arm Reach |

200mm |

|

|

Rotation Range |

±90° |

||

|

J2 Axis |

Arm Reach |

200mm |

|

|

Rotation Range |

±164° |

||

|

Z Axis |

Reach |

±1080° |

|

|

Rotation Range |

210mm |

||

|

Maximum Average Linear Velocity |

1255.45mm/s (with 1.5kg Payload) |

||

|

Repeatability |

±0.03mm |

||

|

Rated Payload |

2kg |

||

|

Max Payload |

3kg |

||

|

Number of Axis |

4 |

||

|

Voltage |

220V/110V 50~60HZ DC 24V |

||

|

Communication |

Wifi/Ethernet |

||

|

Extensibility |

Built-in Motion Controller: with 22 I/O Ports |

||

|

I/O Port |

Digital Input (isolated) |

11 |

|

|

Digital Output (isolated) |

11 |

||

|

Analog Input (4-20mA) |

/ |

||

|

Analog Output (4-20mA) |

/ |

||

|

Height |

578mm |

||

|

Weight |

19kg |

||

|

Footprint |

250x250x10mm |

||

|

Collision Detection |

Supported |

||

|

Drag to Teach |

Supported |

||

Range of Motion and Size

Our Business